Open die forging, also known as free forging, is a metalworking process where a workpiece is hammered or pressed between two flat dies or anvils. The dies do not enclose the entire workpiece, allowing the metal to flow laterally and shape the material. This forging method offers several benefits, making it suitable for various applications. Some of the key benefits of open die forging include:

Customizable Shapes: Open die forging allows for the creation of custom shapes and sizes, making it suitable for producing large, non-standard, or unique components that may be difficult or impractical to manufacture using other methods.

Improved Mechanical Properties: The forging process aligns the grain structure of the metal, resulting in improved mechanical properties, including higher strength, better toughness, and improved fatigue resistance. This makes open die forged parts well-suited for critical applications in industries such as aerospace, oil and gas, and automotive.

Reduced Material Waste: Open die forging can be highly material-efficient since it typically involves minimal machining or material removal compared to other manufacturing processes. This reduces material waste and contributes to cost-effectiveness.

Enhanced Structural Integrity: The absence of seams or joints in open die forged parts leads to enhanced structural integrity and better reliability, especially in applications subjected to high stress or extreme conditions.

Cost-Effective for Low-Volume Production: Open die forging can be economically viable for low-volume production runs or one-off components due to its simplicity and minimal tooling requirements.

Short Lead Times: The open die forging process usually has shorter lead times compared to some other metalworking methods, making it suitable for time-sensitive projects.

Versatility: Open die forging can be used with various metals and alloys, including carbon steels, stainless steels, aluminum, titanium, and nickel-based alloys, allowing for a wide range of applications across different industries.

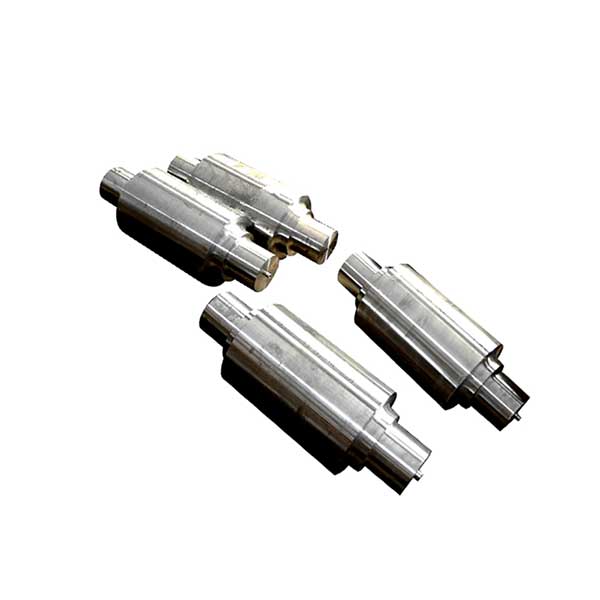

No Size Limitations: Since the workpiece is not confined within a closed die, open die forging can accommodate large or oversized components, making it ideal for forging parts such as shafts, cylinders, and large machinery components.

Improved Grain Flow: The working of the metal during open die forging promotes directional grain flow, leading to improved mechanical properties and better performance of the final product.

While open die forging offers numerous benefits, it is important to note that the process may not provide the same level of precision or complexity achievable through closed-die forging or other advanced shaping methods. The selection of the forging method should be based on the specific requirements of the component, cost considerations, and production volume.