Open die forging, also known as smith forging or blacksmith forging, is a forging process where the metal is deformed between two flat or slightly curved dies that do not completely enclose the workpiece. The process involves the following steps:

Preparing the workpiece: The workpiece is heated to a temperature above its recrystallization temperature, which allows it to become malleable and easier to shape.

Placing the workpiece on the anvil: The heated workpiece is placed on the anvil or the bottom die of the forging press.

Shaping the workpiece: The top die of the forging press is brought down onto the workpiece to shape it. The operator may also use hand tools, such as hammers or tongs, to shape the workpiece.

Reheating the workpiece: The workpiece may need to be reheated periodically to maintain its malleability and prevent cracking.

Repeating the process: The shaping process is repeated until the desired shape and dimensions are achieved.

Finishing the workpiece: Once the desired shape is achieved, the workpiece is cooled and any excess material is removed using machining, grinding, or other finishing processes.

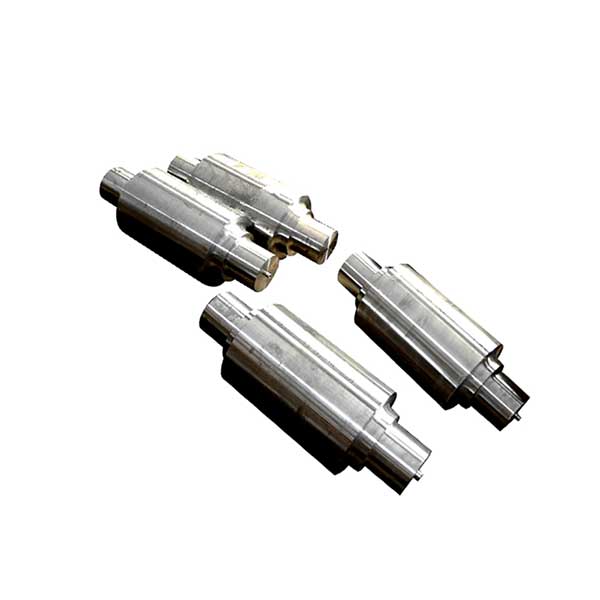

Open die forging is used to create a wide range of products, including large components for machinery, aircraft and aerospace components, and tool and die components. It is a flexible process that can produce unique, custom shapes and sizes with a high degree of precision and strength.