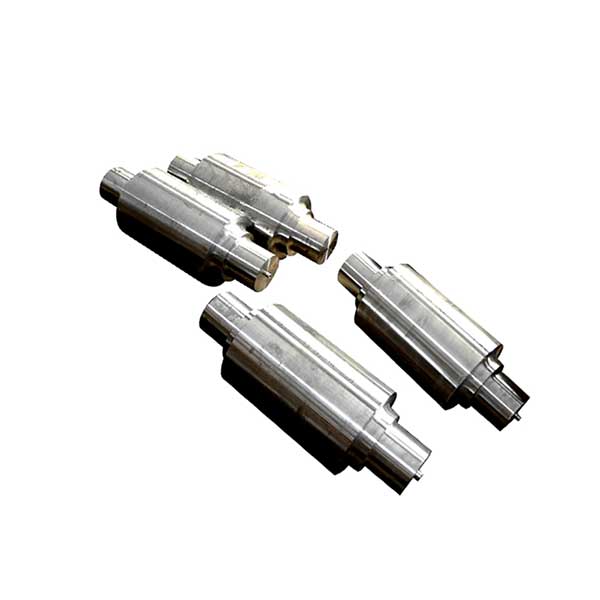

The shaft forging process is a manufacturing method used to produce shafts with superior strength, durability, and reliability. It involves shaping and forming a solid metal billet into the desired shaft shape through the application of heat and pressure.

Shaft forging process

Billet Preparation: The process begins with the selection of a suitable metal billet, typically made of steel or other alloy materials. The billet should have sufficient dimensions to accommodate the final shaft shape.

Heating: The billet is heated in a furnace to a temperature above its recrystallization temperature but below its melting point. This temperature allows the metal to become more malleable and facilitates deformation during the forging process.

Forming: Once the billet reaches the desired temperature, it is transferred to a forging press or hammer. There are two primary forging methods used for shaft production:

a. Open-Die Forging: In open-die forging, the heated billet is placed on a stationary anvil, and repeated blows from a hammer or press deform the metal into the desired shape. The operator guides the deformation by moving the billet between strikes to achieve the desired dimensions.

b. Closed-Die Forging: Closed-die forging involves placing the heated billet between two die halves that contain the desired shape. The dies are then brought together, applying pressure to the billet and forcing it to take the shape of the die cavities. This method provides more precise control over the final shape of the shaft.

Finishing Operations: After the initial forging, the shaft may undergo various finishing operations to refine its shape and dimensions. These operations can include trimming excess material, machining critical features, drilling holes, or grinding the surface to achieve the desired finish.

Heat Treatment: Once the shaft has been formed and finished, it may undergo heat treatment processes such as annealing, quenching, or tempering to enhance its mechanical properties, such as strength, hardness, and toughness. The specific heat treatment process depends on the material composition and desired properties of the shaft.

Inspection and Testing: Quality control measures, including non-destructive testing techniques, are employed to ensure the integrity and reliability of the forged shaft. These inspections may include visual examination, dimensional checks, ultrasonic testing, magnetic particle inspection, or other methods to identify any defects or abnormalities.

Machining and Surface Treatment: If necessary, the forged shaft may undergo additional machining processes, such as turning, milling, or grinding, to achieve precise dimensions or desired surface characteristics. Surface treatments such as coating, plating, or painting may also be applied for corrosion resistance or aesthetic purposes.

By following these steps, the shaft forging process can produce high-quality shafts with improved mechanical properties compared to other manufacturing methods. The resulting shafts exhibit excellent strength, fatigue resistance, and structural integrity, making them suitable for various applications across industries such as automotive, aerospace, machinery, and more.